Magnetic drive pumps are often called magnetic pumps,widely used in chemical industry.The advantage of magnetic pump is seal no leakage,According to the structure divided into magnetic drive centrifugal pump and magnetic drive gear pump two types.

Overview:

Magnetic drive pumps consists of three parts: pump, magnetic drive device and motor.The key component of magnetic drive device is composed of an external magnetic rotor, an internal magnetic rotor and an isolation sleeve without magnetic conduction.When the motor drives the outer magnetic rotor rotating magnetic field can penetrate air gap and the magnetic materials, magnetic drive is connected with the impeller in the rotor synchronous rotation, realize the power out of contact, the dynamic seal into static seal.Due to the pump body, pump shaft, the magnetic rotor of sleeve completely closed.

China Kemai Magnetic Drive Pumps Application

Mainly used in computer water-cooling system, solar fountains, desktop fountain, handicraft, coffee machines, water dispensers, soilless cultivation, water pick, pressurized water heater, hot water circulation, swimming pool water filtration, wash feet massage basin, surfing massage bathtub, auto cooling circulatory system, oiler, humidifier, air conditioner, medical equipment, the cooling system, the product that defend bath, etc.

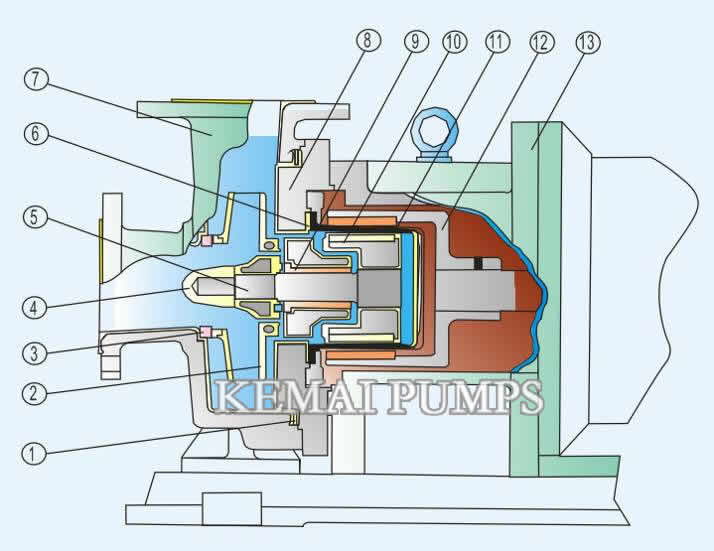

Magnetic Drive Pumps Structure:

According to the pictures

1:pump body

2:Impeller

3:Oral ring

4:Bearing

5:Spindle

6:Gasket ring

7:pump body

8:Pump cover

9:Bearing

10:Rotor

11:Spacer sleeve combination

12:Outside the magnetic

13:Stent

CQ series Stainless steel magnetic pump is the application of modern magnetic theory. No dynamic seal ,It canceled avoids emitting , dropping and leakage , It is widely used in Petro-chemical , medicine, aluminum foil, acid, paint, non-ferrous metals industry and the explosive, volatile, toxic organic solvents and precious liquid.

CQ series Stainless steel magnetic pump is the application of modern magnetic theory. No dynamic seal ,It canceled avoids emitting , dropping and leakage , It is widely used in Petro-chemical , medicine, aluminum foil, acid, paint, non-ferrous metals industry and the explosive, volatile, toxic organic solvents and precious liquid. CS series self-priming magnetic drive centrifugal pump is the perfect combination of self-priming pump and magnetic pump . It uses magnetic coupling drive for no dynamic seal , thus to effectively avoid the phenomena of losing , emitting ,dropping and leaking ,but of outstanding self-priming performance ,Its flow components are made of corrosion-resisting stainless steel ,high-purity industrial porcelain and packing PTFE to maintain sound corrosion resistance .They are extensively used in the industries of medicine ,foodstuff ,alkali production , pharmaceuticals , printing and dyeing , coating etc . to deliver inflammable ,explosive ,volatile ,toxic and organic solvents as well as precious liquid.

CS series self-priming magnetic drive centrifugal pump is the perfect combination of self-priming pump and magnetic pump . It uses magnetic coupling drive for no dynamic seal , thus to effectively avoid the phenomena of losing , emitting ,dropping and leaking ,but of outstanding self-priming performance ,Its flow components are made of corrosion-resisting stainless steel ,high-purity industrial porcelain and packing PTFE to maintain sound corrosion resistance .They are extensively used in the industries of medicine ,foodstuff ,alkali production , pharmaceuticals , printing and dyeing , coating etc . to deliver inflammable ,explosive ,volatile ,toxic and organic solvents as well as precious liquid. CQB series fluoroplastic magnetic driving pumps, magnetic coupling dynamic seals, so thoroughly eliminate the general shaft driving centrifugal pumps running, the shaft seal leakage phenomenon. Its flow components by fluorine plastic and high purity industrial ceramic, excellent corrosion resistance and sealing, therefore, is widely used in chemical industry, medicine, aluminum foil, acid, coating, non-ferrous metal industries and inflammable, explosive, toxic, and volatile organic solvent and precious liquids..

CQB series fluoroplastic magnetic driving pumps, magnetic coupling dynamic seals, so thoroughly eliminate the general shaft driving centrifugal pumps running, the shaft seal leakage phenomenon. Its flow components by fluorine plastic and high purity industrial ceramic, excellent corrosion resistance and sealing, therefore, is widely used in chemical industry, medicine, aluminum foil, acid, coating, non-ferrous metal industries and inflammable, explosive, toxic, and volatile organic solvent and precious liquids.. CFS series of self-suction magnetic drive pumps, self-suction pump is the perfect combination with magnetic pump. Using magnetic coupling dynamic seals, does not exist. So thoroughly that can eliminate the general shaft driving centrifugal pumps running, the shaft seal leakage phenomenon. And has good self-priming function. Its flow components USES corrosion resistance fluorine material. So widely used in pharmaceutical, foodstuff, alkali manufacturing, printing, coating, etc and inflammable, explosive, toxic, and volatile organic solvent and precious liquids.

CFS series of self-suction magnetic drive pumps, self-suction pump is the perfect combination with magnetic pump. Using magnetic coupling dynamic seals, does not exist. So thoroughly that can eliminate the general shaft driving centrifugal pumps running, the shaft seal leakage phenomenon. And has good self-priming function. Its flow components USES corrosion resistance fluorine material. So widely used in pharmaceutical, foodstuff, alkali manufacturing, printing, coating, etc and inflammable, explosive, toxic, and volatile organic solvent and precious liquids. This is a small gear pumps,flow 3~15L/min.pump is made of stainless steel.

This is a small gear pumps,flow 3~15L/min.pump is made of stainless steel.