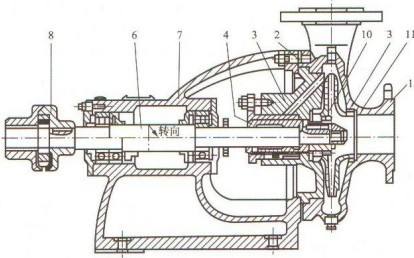

Pump Composition: mainly composed of impeller, pump shell, pump shaft, bearing and packing sealing device and other parts.

First, the major categories are divided according to working principle:

Vane pump can be divided into: centrifugal pump, mixed flow pump, axial flow pump, vortex pump.

Centrifugal pump can be divided into single-stage hot oil pumps, multi – stage pump.

Single pump can be divided into: single suction pump, double suction pump, self – priming pump, non – self – priming pump.

Multistage pump can be divided into: section type, vortex shell type.

Mixed flow pump can be divided into vortex shell type and guide vane type.

Axial flow pump can be divided into fixed blade and adjustable blade.

Vortex pump can also be divided into single suction pump, double suction pump, self – priming pump, non – self – priming pump.

Working principle:

A machine that converts mechanical energy into liquid energy for the purpose of pumping liquids is called gear pump.

(1) positive displacement pump: it USES the periodic change of working chamber volume to transport liquid.

(2) vane pump: use the interaction between vane and liquid to transport liquid.

Specific application:

Pump has different USES, different transport liquid medium, different flow rate, the range of lift, therefore, its structure is of course not the same, the material is also different, in summary, can be divided into:

(1) urban water supply

(2) sewage system

(3) civil and construction system

(4) agricultural water conservancy system

(5) power station system

(6) chemical system

(7) petroleum industry system

(8) mine metallurgy system

(9) light industry system

(10) ship system