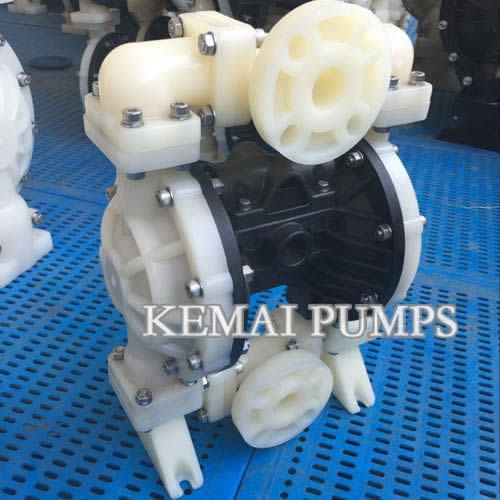

Air Operated Double Diaphragm Pump

Product Description

In china air operated double diaphragm pump is a new type of conveying machine that uses compressed air as the power source for various corrosive liquids, liquid with particles, high viscosity, volatile, flammable and highly toxic liquid.

Pump material: plastic, aluminum, cast iron, stainless steel, teflon

Air Operated Double Diaphragm Pump Basic Overview

AODD pumps is a new type of conveying machine and is the most innovative type of pump in China. Compressed air is used as the power source and can be used for various corrosive liquids.

Pneumatic diaphragm pumps have four materials: engineering plastics, aluminum alloys, cast iron, and stainless steel. Pneumatic diaphragm pumps use nitrile rubber, chloroprene rubber, fluoroelastomer, polytetrafluoroethylene, polytetraethylene, etc. according to different liquid media to meet the needs of different users. Placed in a variety of special occasions, used to pump a variety of conventional pump can not pump the media, have achieved satisfactory results.

Air operated double diaphragm pump applications occasion

Because of the above characteristics of the air operated double diaphragm pump, Diaphragm pump has gradually invaded the market of other pumps since its birth and is part of it. Such as: spray diaphragm, ceramic industry, pump has occupied an absolute dominant position, while in other industries, such as environmental protection, wastewater treatment, construction, sewage, fine chemicals are expanding its market share, and other pumps can not Alternative status.

Pneumatic diaphragm pump is a new type of conveying machine that uses compressed gas as the power source. It can exhaust all kinds of corrosive liquids, liquid with particles, high viscosity, volatile, flammable and highly toxic liquid. . The diaphragm pump is available in four materials: plastic, aluminum alloy, cast iron, and stainless steel. Pneumatic diaphragm pumps are made of nitrile rubber, neoprene, fluororubber, polytetrafluoroethylene, and polytetramethylene according to different liquid media. To meet the needs of different users. It is placed in various special occasions and used to pump various media that cannot be pumped by conventional pumps, and has achieved satisfactory results.

1. Due to the use of gas as the power, the flow rate is actively adjusted with the change of back pressure (outlet resistance), which is suitable for medium and high viscosity fluids. The working point of the centrifugal pump is set based on water. If it is used for fluid with a slightly higher viscosity, it must be equipped with a reducer or a frequency converter. The cost is greatly improved, as is the case with gear pumps.

2. Pneumatic pumps in flammable and explosive environments is reliable and low cost, such as the transportation of fuel, gunpowder and explosives, because:

First, it is impossible to generate sparks after grounding;

Second, no heat is generated during the work, and the machine will not overheat;

Third, the fluid does not overheat because the pneumatic diaphragm pump minimizes the agitation of the fluid.

3. In the center of the construction site, such as the construction of construction sites, industrial and mining wastewater discharge, due to the impurities in the sewage and complex components, the pipeline is prone to infarction, thus forming an environment with excessive load on the electric pump, the motor is hot and vulnerable. The pneumatic diaphragm pump can pass through the pellets and the flow rate is adjustable, and the pipeline is actively stopped when the pipeline is infarction.

4. In addition, the air operated double diaphragm pump is small in size, easy to move, requires no foundation, has a small footprint, and is simple and economical to install. It can be used as a moving material pump.

5, in hazardous, corrosive material processing, the diaphragm pump can completely isolate the material from the outside world.

6, or some experiments to ensure that no impurities contaminate the raw materials.

7, can be used to transport fluids with relatively unstable chemical properties, such as: photosensitive materials, flocculants and so on. This is because the diaphragm pump has a low shear force and a small physical impact on the material.

Applicable industry of Air Operated Double Diaphragm Pump

Chemical industry: acid, alkali, solvent, suspension, dispersion system.

Petrochemical industry: heavy oil, grease, mud, sludge, etc.

Coatings industry: resins, solvents, colorants, paints, etc.

Japanese chemical industry: detergents, shampoos, lotions, emulsions, hand creams, surfactants.

Ceramic industry: mud, porcelain, lime, clay.

Mining industry: coal slurry, magma, mud, mortar, oil transfer, etc.

Water treatment: lime slurry, soft sediment, sewage, chemicals, wastewater.

Food industry: liquid semi-solid, chocolate, salt water, vinegar, syrup, vegetable oil, soybean oil, honey.

Beverage industry: yeast, syrup, concentrate, gas-liquid mixture, wine, juice, corn syrup, etc.

Pharmaceutical industry: solvent, acid, alkali, plant extract, ointment and other pharmaceutical materials.

Paper industry: binders, resins, paints, inks, pigments, hydrogen peroxide, etc.

Electronics industry: solvents, plating solutions, cleaning solutions, nitric acid, waste acid, corrosive acids, polishing fluids.

Textile industry: dye chemicals, resins, glues, etc.

Construction industry: cement slurry, ceramic tile adhesive, rock slurry, ceiling finish, etc.

Automotive industry: polishing emulsions, oils, coolants, automotive primers, oil latexes, varnishes, varnish additives, degreasing liquids, paints, etc.

Furniture industry: binders, varnishes, dispersion systems, solvents, colorants, white wood glue, epoxy resin, starch binder.

Metallurgy, foundry and dyeing industries: metal paste, hydroxide and charcoal pulp, dust washing pulp, etc.

PX series AODD pump flow and head:

| Model | Max.Flow (L/min) |

Max.Head (m) |

Suction and discharge size (inch) |

Particle Diameter (mm) |

| PX-06/10 | 27 | 70 | 1/4–3/8 | 1.6 |

| PX-15 | 57 | 84 | 1/2–3/4 | 2.5 |

| PX-25 | 157 | 84 | 1/2 | 4 |

| PX-40 | 358 | 84 | 1 1/2 | 5 |

| PX-50 | 587 | 84 | 2 | 6 |

| PX-80 | 1060 | 84 | 3 | 9.4 |