Feed Type Stainless Steel Single Screw Pump

Feed Type Stainless Steel Single Screw Pump

Model range: G15-1 ~ G55-1

Applicable medium temperature :-10℃~ +150℃

Flow range: 1m3/h ~ 18m3/h

Head range: 10m ~ 60m

Motor power: 0.55kw ~ 7.5kw

Revolution: 960 r/min

Product Description

Working principle:

Food grade screw pump is a new type of pump according to the principle of moving meshing displacement, the main working parts are eccentric screw (rotor) and fixed bushing (stator).

Due to the special geometry of the two parts, separate sealing cavity is formed, the medium is pushed evenly by the axial direction to flow, the internal flow rate is low, the volume remains unchanged, the pressure is stable, so there will be no vortex and agitation.The output pressure of each pump is 0.6mpa and the head is 60m(clear water). It is suitable for the temperature of conveying medium below 80℃ (up to 150℃ for special requirements).

Because the stator is made of a variety of elastic materials, so the pump for the transport of high viscosity fluid and medium containing hard suspended particles or containing fiber medium, there is a general type of pump can not be competent.The flow rate is proportional to the speed.

The transmission may adopt the coupling direct transmission, or adopt the speed-regulating motor, the triangle belt, the gearbox and other devices to change speed.

This kind of pump parts less, compact structure, small volume, simple maintenance, rotor and stator is the vulnerable parts of the pump, simple structure, easy to assemble and disassemble.

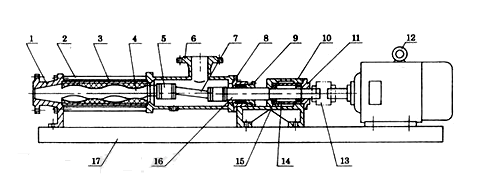

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| discharge cavity | tie rod | screw rubber sleeve | screw shaft | universal joint assembly | suction body | joint shaft | filler | packing gland |

| 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | |

| bearing seat | Bearing cover | motor | coupling | bushing | bearing | transmission spindle | base |

Performance Parameter List:

| Model | Speed r/min |

Flow m3/h |

Motor KW |

Allowable Particle Diameter mm |

Allowable Fiber Length mm |

| G15-1 | 960 | 1 | 0.55 | 1.5 | 15 |

| G20-1 | 960 | 1.5 | 0.75 | 3.5 | 20 |

| G25-1 | 960 | 2 | 1.1 | 4.5 | 26 |

| G30-1 | 960 | 3 | 1.5 | 5 | 30 |

| G35-1 | 960 | 5 | 2.2 | 5.7 | 35 |

| G40-1 | 960 | 7 | 3 | 7.1 | 40 |

| G45-1 | 960 | 9 | 4 | 8 | 45 |

| G50-1 | 960 | 13 | 5.5 | 9 | 51 |

| G55-1 | 960 | 18 | 7.5 | 10 | 55 |