YCB-G model heat insulating gear pump

Product Description

Model explanation

YCB 25 – 0.6 G

YCB: Gear pump

25: Flow 25M3/H

0.6: Differential pressure 0.6MPA

G: Heat insulating type

YCB-G Gear Pump Application scope

1. Heavy oil industry

2. Asphalt industry

3. Resin industry

4. Detergent industry

5. Glues industry

Performance scope

1. temperature: -10 °C~300°C

2. viscosity : 5~1500cst

YCB-G Brief introduction

YCB-G model heat insulating gear pump is used to transfer different medium, such as heavy oil, asphalt, resin, detergent and glue, which not includes solid particles and the temperature not higher than 300℃, with solidifying character under the normal temperature. It also applies to the site with heat-insulated requirement in the process technology and outdoors installation at very cold area.

This series of heat insulation gear pump belongs to external gear pump. The tooth form is composite formed by arc and sine curve .It could transfer many kinds of medium with steady output flow and pressure. There are heat insulating jacket and inlet and outlet joints on the pump casing, so it could adopt the media, such as heat-conducting oil, steam .hot water and cold water to heat, keep warm and cooling the transferred medium and pump. When the viscosity of transferred medium is larger than 1500cSt, speed should be reduced.

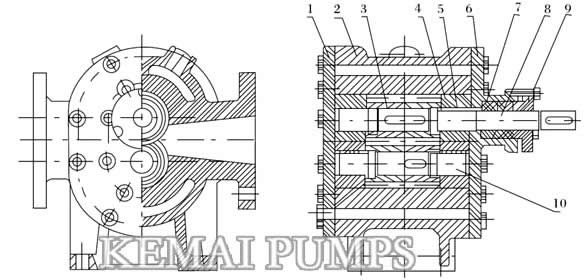

Gear Pump Construction

1:Back cover

1:Back cover

2:Pump body

3:Gear

4:Bearing stand

5:Bush

6:Front cover

7:Seal ring

8:Driving shaft

9:End cover

10:Driven shaft

Kemai Pumps YCB-G series heat insulation gear pump has simple and compact structure. It is convenient for use and maintenance. The main parts adopt high quality steel with precise processing, so it has good quality. It has good performance of self-priming, so it needs not to be filled oil before operation the pump every time. Watch the pump from motor, the rotation direction is clockwise. (left suction, right discharge)

1. Pump body

One pair of gears and four bearing stands were set in the hole of pump body. The front cover and the back cover and the back cover were set at ahead and behind. User could connect the pipe line by using flanges at both sides, and connect the heat insulation medium to preserve heat of chamber of pump by using two screwed holes on the top of pump body.

2. Gear and shaft

Spiral gear and shaft compose of shaft-gear. The helical shaft gear and herringbone shaft gear could be adopted according to different specifications of capacity.

3. Bearing stand and bush (Sliding bearing)

After the bearing stand and bush are fitted together, put them into the pump body and support the gear operation

4. Gasket

Gasket is put at compact plane between the pump body and front or back cover; it enhance the seal ability of jointing plane.

5. Shaft seal

Shaft seal has axial sealing function for the input shaft end of pump. There is shaft-packing room on the front cover of pump. It could be equipped with mechanical seal or packing.

Structure Drawing

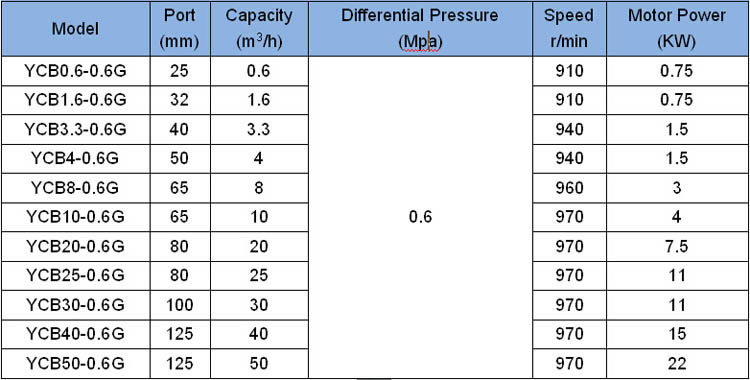

YCB-G Gear pump flow and head data sheet